Sadly Yuneec CS wasn't much help. The standard response of you can send it to us for "warranty inspection" spiel even after providing photo evidence. Turn around time right now is approximately 4 weeks with an additional week each way for coast to coast ground shipping. Another month and a half on top of the three weeks of not being able to use the device for its intended purpose. Was hoping I could get one that would be guaranteed problem free from Yuneec, but not the case. Going to return this one and try the lottery one more time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yuneec Q500 4K thoughts

- Thread starter OregonDrone

- Start date

- Joined

- Feb 23, 2016

- Messages

- 12

- Reaction score

- 4

- Age

- 70

No word yet from Yuneec in response to my email to CS. Since Yuneec has acknowledged that this is now a "known issue" I would think they're on the stick as far as rectifying it, and by rectifying, I do NOT mean simply exchanging for a new frame/body with the same design/material flaw. As much as I didn't like the FAA registration thing, I should think that if enough people complained, there could be some sort of action taken at that level. This has already been pointed out as a potential safety issue so I would think that the FAA might be concerned. If a motor busted off and caused a crash, property damage and/or personal injury could be a result. Has anybody heard of a mandatory UAV recall - like what happens with defective cars? One of the members here asked people to report and since he didn't hear of anything, assumed that it was a short term manufacturing issue. I'm thinking that it's likely a minority of Typhoon owners that spend any time of these forums(?) I'm posting this info on other sites and it's not likely going to stop there.

It's been discussed before (maybe not here), there is not one issue of a Q falling out of the sky due to a motor coming off the mounts. In this day and age of Social Media, we'd have heard about it.No word yet from Yuneec in response to my email to CS. Since Yuneec has acknowledged that this is now a "known issue" I would think they're on the stick as far as rectifying it, and by rectifying, I do NOT mean simply exchanging for a new frame/body with the same design/material flaw. As much as I didn't like the FAA registration thing, I should think that if enough people complained, there could be some sort of action taken at that level. This has already been pointed out as a potential safety issue so I would think that the FAA might be concerned. If a motor busted off and caused a crash, property damage and/or personal injury could be a result. Has anybody heard of a mandatory UAV recall - like what happens with defective cars? One of the members here asked people to report and since he didn't hear of anything, assumed that it was a short term manufacturing issue. I'm thinking that it's likely a minority of Typhoon owners that spend any time of these forums(?) I'm posting this info on other sites and it's not likely going to stop there.

Even vehicles, where Bodily injury and death are certainly much more of a risk, it still takes a disturbing amount of "defective" failures to make it a recall - even voluntary.

We have not had a failure yet. Just a portion of people noticing cracks.

- Joined

- Dec 31, 2015

- Messages

- 136

- Reaction score

- 53

- Age

- 54

I've been as careful with my Typhoon as anyone could possibly be. Never crashed, never tipped over, props have never touched anything. All 4 of my motor mounts are cracked! I'm absolutely certain that if any Yuneec owner checks, he will find cracks. Sticks, is Yuneec paying you? Because it seems like you are in denial that Yuneec could do no wrong. I'm not bashing them but this is a REAL problem that desperately needs solving if they're going to continue as a successful company.Just a portion of people noticing cracks.

- Joined

- Feb 23, 2016

- Messages

- 12

- Reaction score

- 4

- Age

- 70

"Even vehicles, where Bodily injury and death are certainly much more of a risk, it still takes a disturbing amount of "defective" failures to make it a recall - even voluntary."

Hi Sticks -

Your point is well taken. The National Highway Traffic Safety Administration does seem a bit slow on the take sometimes. Automakers have a lot of political clout. That said, I believe the FAA is far more stringent where it comes to airborne vehicles... with real planes for instance you must maintain a maintenance log, etc. Pilot error is a tough one to solve but having things fall from the sky due to mechanical or design failures is another.

"We have not had a failure yet. Just a portion of people noticing cracks."

I can't help but wonder what portion of owners are noticing and what portion don't know to look. So far on this forum, it looks as if many who have checked have found them and it looks like some cracks are spreading beyond the screw flange. It may indeed be a matter of "yet."

At some point if a Typhoon comes down due to a busted mount and causes some serious harm or damage it may be a different story... I.E. what did Yuneec know and when did they know it?

Still no reply to my email from Yuneec....

Hi Sticks -

Your point is well taken. The National Highway Traffic Safety Administration does seem a bit slow on the take sometimes. Automakers have a lot of political clout. That said, I believe the FAA is far more stringent where it comes to airborne vehicles... with real planes for instance you must maintain a maintenance log, etc. Pilot error is a tough one to solve but having things fall from the sky due to mechanical or design failures is another.

"We have not had a failure yet. Just a portion of people noticing cracks."

I can't help but wonder what portion of owners are noticing and what portion don't know to look. So far on this forum, it looks as if many who have checked have found them and it looks like some cracks are spreading beyond the screw flange. It may indeed be a matter of "yet."

At some point if a Typhoon comes down due to a busted mount and causes some serious harm or damage it may be a different story... I.E. what did Yuneec know and when did they know it?

Still no reply to my email from Yuneec....

I'm not getting paid by anybody.

I am just tired of reading threads like this acting like the sky is falling. Making a bigger deal of this than it is.

Some have cracked mounts, some don't, not one single instance that I or anyone else that has chimed in on the subject of a motor breaking off during flight. Not even a partial break/wobbly motor observed on landing or post flight inspection.

DJI phantom quads have worse cracking around their mounts, and same thing, no reports of motor separation. DJI has been in the game longer.

Is it a problem - Yes. Is it a ground all Q500s until something is done about it - **** no. Is it something that Yuneec needs to take seriously - Yes, and they are. Don't expect a free replacement frame section, or paid upfit if you send yours in to have something done about it. Certainly don't expect a refund.

If a person has an issue with the cracking frame mounts, then craigslist your quad, and go buy another brand. If this is the make or brake issue on if they are going to buy one, then don't.

Mine did a nasty aerial landing in a tree last month, then upon extraction, took a 50' fall and landed flat on her back, breaking the second of two CF props on it. I had the cracked rubber grommets, not sure if I have any frame cracks, but I know I have one motor that now has shaft play. Motors are still firmly attached. This is why I am not concerned. I have a motor with shaft play, a repaired gimbal mount, and a broken belly (crack across the underside between the gimbal and the mid section). Warranty is expired now that I crashed it, and it is still air worthy.

I am just tired of reading threads like this acting like the sky is falling. Making a bigger deal of this than it is.

Some have cracked mounts, some don't, not one single instance that I or anyone else that has chimed in on the subject of a motor breaking off during flight. Not even a partial break/wobbly motor observed on landing or post flight inspection.

DJI phantom quads have worse cracking around their mounts, and same thing, no reports of motor separation. DJI has been in the game longer.

Is it a problem - Yes. Is it a ground all Q500s until something is done about it - **** no. Is it something that Yuneec needs to take seriously - Yes, and they are. Don't expect a free replacement frame section, or paid upfit if you send yours in to have something done about it. Certainly don't expect a refund.

If a person has an issue with the cracking frame mounts, then craigslist your quad, and go buy another brand. If this is the make or brake issue on if they are going to buy one, then don't.

Mine did a nasty aerial landing in a tree last month, then upon extraction, took a 50' fall and landed flat on her back, breaking the second of two CF props on it. I had the cracked rubber grommets, not sure if I have any frame cracks, but I know I have one motor that now has shaft play. Motors are still firmly attached. This is why I am not concerned. I have a motor with shaft play, a repaired gimbal mount, and a broken belly (crack across the underside between the gimbal and the mid section). Warranty is expired now that I crashed it, and it is still air worthy.

Last edited:

- Joined

- Dec 31, 2015

- Messages

- 136

- Reaction score

- 53

- Age

- 54

You're indeed correct, it's not a reason to ground every Q500 but discussing the good and the bad is exactly what forums like this are for. Please don't bash us for making an attempt to resolve these problems. Yuneec, as a company, is great and has relatively few issues so it shouldn't be a problem for them to come up with a reasonable solution.I am just tired of reading threads like this acting like the sky is falling. Making a bigger deal of this than it is.

Tell me, what would you think would be a "reasonable solution?"

I'm not bashing anyone, just trying to get people to step back and think before they yell "DANGER DANGER...DEATH AND DESTRUCTION"

I'm not bashing anyone, just trying to get people to step back and think before they yell "DANGER DANGER...DEATH AND DESTRUCTION"

- Joined

- Dec 31, 2015

- Messages

- 136

- Reaction score

- 53

- Age

- 54

I get it. It's not the end of the world. As far as a solution though, I'm already in the process of making my own fix. I have some left over 1/16th" carbon fiber to fabricate into 8 plates. I'm grinding away the plastic rings around the motor mounting screws. Then sandwich the mount with a carbon fiber plate on each side with some epoxy. Remount motors. It should be a permanent fix and give me piece of mind. If it works, I'll post pics of the repair.

- Joined

- Feb 23, 2016

- Messages

- 12

- Reaction score

- 4

- Age

- 70

Hi Sticks...

I love it when someone takes something I have said and cranks it up about 5-6 notches. HAHA

Seriously, I think it would be nice if Yuneec came up with some sort of reinforcement device - maybe something like those aluminum discs that would help bridge any potential cracking of the mount itself. As I see it, the ESCs circuit board is about the only thing doing that job now. They could pop out a bunch of those, notify owners and send them the discs for free or offer to install. No big deal, right?

Maybe I am an alarmist but after spending close to a grand, I'm a little bent out of shape to have discovered this issue too late. As mentioned, I haven't even received mine yet. Not sure if I should open it when I do.

I love it when someone takes something I have said and cranks it up about 5-6 notches. HAHA

Seriously, I think it would be nice if Yuneec came up with some sort of reinforcement device - maybe something like those aluminum discs that would help bridge any potential cracking of the mount itself. As I see it, the ESCs circuit board is about the only thing doing that job now. They could pop out a bunch of those, notify owners and send them the discs for free or offer to install. No big deal, right?

Maybe I am an alarmist but after spending close to a grand, I'm a little bent out of shape to have discovered this issue too late. As mentioned, I haven't even received mine yet. Not sure if I should open it when I do.

I get it. It's not the end of the world. As far as a solution though, I'm already in the process of making my own fix. I have some left over 1/16th" carbon fiber to fabricate into 8 plates. I'm grinding away the plastic rings around the motor mounting screws. Then sandwich the mount with a carbon fiber plate on each side with some epoxy. Remount motors. It should be a permanent fix and give me piece of mind. If it works, I'll post pics of the repair.

Start a new thread, take pictures and maybe the mods will make it a sticky.

Seesfarther -

Then don't open it, send it back/cancel the order. Odds are good you will find at least one cracked grommet upon opening. I spent $1400 on my first kit, and then another $1k on my second (first one will likely be organ donor, painful lesson learned about FPV, LOS, and the Q500 innate attraction to wood in it's natural form). I looked at my new one, and I have one of the 8 grommets that is cracked - NIB from Carolina Dronz.

I've read about lots of other crashed Q500s that require a frame replacement because they managed to break an entire arm off, and then they noticed the mount cracks when they were taking it apart- yet the motors still attached.

Last edited:

- Joined

- Feb 23, 2016

- Messages

- 12

- Reaction score

- 4

- Age

- 70

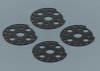

"I get it. It's not the end of the world. As far as a solution though, I'm already in the process of making my own fix. I have some left over 1/16th" carbon fiber to fabricate into 8 plates. I'm grinding away the plastic rings around the motor mounting screws. Then sandwich the mount with a carbon fiber plate on each side with some epoxy. Remount motors. It should be a permanent fix and give me piece of mind. If it works, I'll post pics of the repair."

Yeah - something like that?

Yeah - something like that?

Carbon Fibre motor mount plates are now available to reinforce the frame under the motors and prevent the cracking problems.

What you find when not looking for more info

Yuneec Typhoon Q500, Q500+, Q500-4k, Carbon Fiber Motor Reinforcement Mounts

What you find when not looking for more info

Yuneec Typhoon Q500, Q500+, Q500-4k, Carbon Fiber Motor Reinforcement Mounts

Attachments

Last edited:

- Joined

- Mar 19, 2016

- Messages

- 8

- Reaction score

- 3

- Age

- 57

I've been as careful with my Typhoon as anyone could possibly be. Never crashed, never tipped over, props have never touched anything. All 4 of my motor mounts are cracked! I'm absolutely certain that if any Yuneec owner checks, he will find cracks. Sticks, is Yuneec paying you? Because it seems like you are in denial that Yuneec could do no wrong. I'm not bashing them but this is a REAL problem that desperately needs solving if they're going to continue as a successful company.

Just out of curiosity, do you use the white "wrench" tool when putting your props on and taking them off again, or do you grip the prop in one hand and give the motor a full turn under the prop with the other? I thought that wrench was just too much "cruel and unusual punishment" for the motor mounts, so I developed an alternative for myself. That prop was after all designed to hold its share of a couple lbs always with the direction of the force hopefully not twisting.

That is my thinking, and why I'm curious if the wrench is a common factor.

Cheers!

Kurt

The only time I use the wrench is when I put my CF props on, as they don't make sufficient contact with the rubber compression rings.

I wonder if the cracks appear on some and not others because of the way they are tightened when built? If real tight then the rubber mount washer does not have a chance to work. If too loose then the motor would be able to wobble around. I would think either case could lead to cracking of the plastic.

Just checked mine after I dumb thumbed it into the tip top of a tree, no cracks. The allen wrench I used to remove the screws was one of those with a 1/4" hex head used in power drivers. Just used it in my fingers so I didn't have a great handle. Was able to easily overcome the locktite and remove the screws. I would judge that they just had the rubber slightly compressed, no more.

Got the repair parts ordered, new frame and 2 props, should be good as new, minus decals.

Broke both front motors off in the fall.

Just checked mine after I dumb thumbed it into the tip top of a tree, no cracks. The allen wrench I used to remove the screws was one of those with a 1/4" hex head used in power drivers. Just used it in my fingers so I didn't have a great handle. Was able to easily overcome the locktite and remove the screws. I would judge that they just had the rubber slightly compressed, no more.

Got the repair parts ordered, new frame and 2 props, should be good as new, minus decals.

Broke both front motors off in the fall.

- Joined

- Dec 31, 2015

- Messages

- 136

- Reaction score

- 53

- Age

- 54

I've never used the nutcrackerJust out of curiosity, do you use the white "wrench" tool when putting your props on and taking them off again, or do you grip the prop in one hand and give the motor a full turn under the prop with the other? I thought that wrench was just too much "cruel and unusual punishment" for the motor mounts, so I developed an alternative for myself. That prop was after all designed to hold its share of a couple lbs always with the direction of the force hopefully not twisting.

That is my thinking, and why I'm curious if the wrench is a common factor.

Cheers!

Kurt

- Joined

- Mar 19, 2016

- Messages

- 8

- Reaction score

- 3

- Age

- 57

Similar threads

- Replies

- 1

- Views

- 423

- Replies

- 12

- Views

- 511

- Replies

- 14

- Views

- 833