I have a typhoon

The landing gear is not working properly.

When I try to make the landing gear go up it will not.

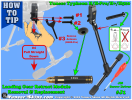

Watched a video on landing gear.

Turned the drone upside down. Preformed the test in the video. One will up about 1/4 of the way. I can also hear the motor run. The other side I hear nothing.

Looked at another video.

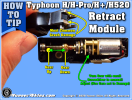

I took them both off the drone.

Used a 9 volt to test them. They worked fine.

I also tried cleaning the thermals.

Where do I go from here?

Thank you

Mike

The landing gear is not working properly.

When I try to make the landing gear go up it will not.

Watched a video on landing gear.

Turned the drone upside down. Preformed the test in the video. One will up about 1/4 of the way. I can also hear the motor run. The other side I hear nothing.

Looked at another video.

I took them both off the drone.

Used a 9 volt to test them. They worked fine.

I also tried cleaning the thermals.

Where do I go from here?

Thank you

Mike