I seem to recall the A and B arms are actually identical. In fact I believe the motors may also be the same. The difference in rotation being the position where it is connected to the ESC and the A/B quick attachment for the props.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Jul 18, 2016

- Messages

- 69

- Reaction score

- 44

- Age

- 61

What do you need pictures of? I have parts of the Typhoon H that I can take closeup's of with a scale.

- Joined

- Mar 4, 2019

- Messages

- 488

- Reaction score

- 279

- Age

- 56

Just glancing through this post, I saw a few things I wanted to touch on.

The 3D model I listed is a raw model and would need to be reworked by measuring the actual parts and using software like Freecad or Blender. It takes a lot of time and time is something I am short on lately.

I build and sell 3D printers, laser engravers/cutters, and robotic arms as a secondary hobby to my drone collection. I have limited knowledge when it comes to creating and designing STL files.

STL files are one type of file used by Klipper or Marlin firmware to print your project using a 3D printer.

Depending on the part you need, you could use a newer iPhone 12 Pro with the LiDAR camera to scan the part and use the scan to create an STL file. This would be the easiest and fastest way.

The type of filament (3D printer ink) you use to print your parts is crucial. PETG filament is best for anything that may take a hit or crash. PLA filament is sturdy but has a low tolerance to heat from the sun.

You can also use carbon fiber filament to print some parts but keep in mind that certain parts are designed to have a bit of flex to them.

I have several of the arms you are in need of and depending on your location, could make you a good deal on them.

You can also check with YuneedSkins. John, the owner, has the largest inventory of Yuneec drone parts in the US. His prices are fair and he is a good guy.

I can also print parts as long as you can provide the STL file. Keep in mind that 3D printing is done in layers and some sanding may be required.

When I have the time, I do plan on using the CAD model of the Typhoon H to make some STL files but as I said before, I am short on time these days.

If I can help you in any way, don't hesitate to ask.

Have a great day,

The 3D model I listed is a raw model and would need to be reworked by measuring the actual parts and using software like Freecad or Blender. It takes a lot of time and time is something I am short on lately.

I build and sell 3D printers, laser engravers/cutters, and robotic arms as a secondary hobby to my drone collection. I have limited knowledge when it comes to creating and designing STL files.

STL files are one type of file used by Klipper or Marlin firmware to print your project using a 3D printer.

Depending on the part you need, you could use a newer iPhone 12 Pro with the LiDAR camera to scan the part and use the scan to create an STL file. This would be the easiest and fastest way.

The type of filament (3D printer ink) you use to print your parts is crucial. PETG filament is best for anything that may take a hit or crash. PLA filament is sturdy but has a low tolerance to heat from the sun.

You can also use carbon fiber filament to print some parts but keep in mind that certain parts are designed to have a bit of flex to them.

I have several of the arms you are in need of and depending on your location, could make you a good deal on them.

You can also check with YuneedSkins. John, the owner, has the largest inventory of Yuneec drone parts in the US. His prices are fair and he is a good guy.

I can also print parts as long as you can provide the STL file. Keep in mind that 3D printing is done in layers and some sanding may be required.

When I have the time, I do plan on using the CAD model of the Typhoon H to make some STL files but as I said before, I am short on time these days.

If I can help you in any way, don't hesitate to ask.

Have a great day,

Last edited:

- Joined

- Mar 4, 2019

- Messages

- 488

- Reaction score

- 279

- Age

- 56

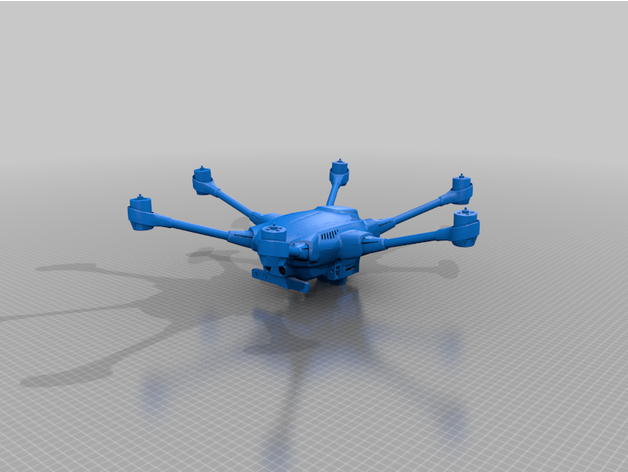

Yuneec Typhoon H by cabinfourus

These are some 3d files for the Yuneec Typhoon H drone. I am sharing them in hopes that others can help out with the designs.

Dead way to get success. STL files are not design files. Design is drawn. The 3D scanner is good for one more Ken or Barbie toy. Engineering design is a bit more complicated. More than that, 3D prints are weight and not strong enough.

- Joined

- Mar 4, 2019

- Messages

- 488

- Reaction score

- 279

- Age

- 56

I have been 3D printing and designing for about 10 years now. The strength of the filaments depends on which one you use. As far as the weight, some filaments are lighter than the original parts and much stronger. Drone manufacturing is performed on assembly lines and they use the cheapest plastic parts possible without affecting the design or integrity. I can print with carbon fiber, so it holds up pretty well for drones. PETG is a good choice also. I built the DJI Inspire clone from this website and it is still in the air.Dead way to get success. STL files are not design files. Design is drawn. The 3D scanner is good for one more Ken or Barbie toy. Engineering design is a bit more complicated. More than that, 3D prints are weight and not strong enough.

DJI Inspire 3D Printable Quadcopter V1.5! - RC Groups!

There are many cloned drone designs people have built and used for their hobbies or business that work well.

For the design of STL files, I use different software like Blender or Adobe. Drawing out the plan is a start but ultimately 3D design is engineered through software or scanning. I use an intel real sense 415 camera, along with the Xbox Kinect sensor to scan objects for printing. I recently scanned a Holy Stone HS720E body for a friend. He printed it with PETG and says it is better than the original body.

The 3D printers and scanners I built for myself are used for much more than printing Ken or Barbie toys. I have thousands tied up in these machines that use Raspberry Pi 4 and Makerbase boards with Klipper firmware to drive them. There are some cheap Chinese 3D printers that are only good for printing small projects but I can print an object as large as 1000mm by 1000mm by 500mm. As long as my settings are correct, the precision of my prints can have a precision of .05mm. Lastly, depending on the filament, the prints can be as good as, if not better than the original.

I have a lot of knowledge I earned from the University of a Google Search Bar with 3D printers, 3D scanners, and also laser cutters. The one thing I really suck at is coding the firmware to work with self-built robotics but I am getting better. C;

One last thing, don't waste any time with the cheap 3D scanners. The quality of the scans is really bad. Things like screw threads will scan but turn into more of a lump of plastic when you print it. Look into building your own or purchase the more expensive scanners with better quality.

Last edited:

- Joined

- Mar 4, 2019

- Messages

- 488

- Reaction score

- 279

- Age

- 56

You would be correct. I used spare parts from several I purchased from people who had crashed them to build a couple of extras. The arms are identical. The motors are identical. The ESC controls the direction.I seem to recall the A and B arms are actually identical. In fact I believe the motors may also be the same. The difference in rotation being the position where it is connected to the ESC and the A/B quick attachment for the props.

Similar threads

- Replies

- 17

- Views

- 424

- Replies

- 23

- Views

- 671

- Replies

- 3

- Views

- 393

- Replies

- 7

- Views

- 1K

- Replies

- 2

- Views

- 702