- Joined

- Mar 22, 2020

- Messages

- 134

- Reaction score

- 67

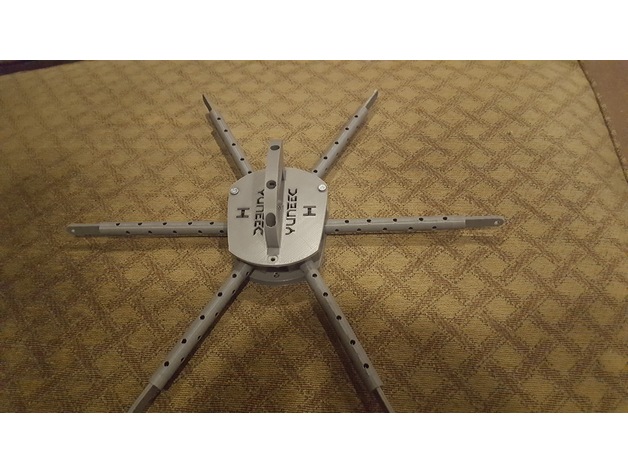

Ok I have been working on this Broke Arm Clip issue. I designed an assembly that can hold up any amount of broken arms there are.

Already flight tested with no camera and was a success . Will test later on with cam on. This is a work in progress, print more pieces as we speak, and will have a similar setup to do essentially the same for the legs. Let me know what you all think, once the design is all printed and test fitted it will be uploaded to Thingverse. For Free, I think you will like it.

. Will test later on with cam on. This is a work in progress, print more pieces as we speak, and will have a similar setup to do essentially the same for the legs. Let me know what you all think, once the design is all printed and test fitted it will be uploaded to Thingverse. For Free, I think you will like it.

Any Questions?

Already flight tested with no camera and was a success

Any Questions?

Last edited: